Whites of Utica*

by David Roche

|

| Fig. 1 – A copy of a Mettlach stein, #6, 10¾" body height. Also made with bases #5 through #8 with body heights from 10½" to 12¼". |

Whenever we notice a blue stoneware beer mug or stein, we automatically assume that it was produced in Germany. In most cases we would be correct, with one noticeable exception: those made by Whites of Utica. Whites was started in 1839 by Noah White who was a barge pilot on the Erie Canal which ran from Albany to Buffalo, New York. Because of its prime geographical location, Utica was obviously an ideal spot for a pottery factory. The waterway could be used to transport clay northward from the clay-rich areas of New Jersey and to return the finished products to the marketable areas such as New York City, Boston and Philadelphia. Noah White eventually settled in Utica where he bought a pottery business owned by Samuel Addington and renamed it Whites of Utica. In 1849 Noah and his two sons, Nicholas and William, formed a partnership. The mark used on their wares at that time was simply Whites Utica or White’s Utica. In 1863 Noah’s grandson, William N. White, joined the firm and the name was changed to Noah White, Son & Co. William took over the firm’s management upon Noah’s death in 1865.

|

| Fig. 2 — Impressed base mark: WHITES POTTERY UTICA NY. |

In the 1870s a new building was added, expanding the operation, which both modernized and improved production processes. A 65-horsepower steam engine was also added. Whites’ major production items included jugs, chums, chamber pots, preserve jars, beer bottles, and fire bricks. In 1887 William’s son, Charles N. White, took over the management. The pottery ceased production in 1910 after 71 years of uninterrupted stoneware manufacture. Toward the end of the 19th century, competition from stoneware factories in Ohio and the use of glass containers created serious problems for New York potteries. The competition forced Whites to expand its range of products considerably and cupola brick, gas and oven tile and beer steins were added. Production of beer mugs and steins was first introduced in 1885. In 1894, a German artist named Hugo Billhardt was hired. He was responsible for mold designing and introducing the German designs we often see. He worked there until 1901.

During their heyday Whites employed between 20 and 25 workers. They used the rich New Jersey clay in two of their three kilns which were geared for stoneware firing. The third kiln was used for bricks. The two stoneware kilns were fired with slab wood, mostly spruce, which took approximately six to eight days for the saltglazed items and approximately forty-eight hours for the bristol glaze pieces.

|

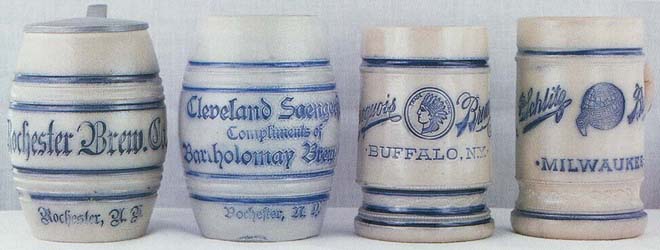

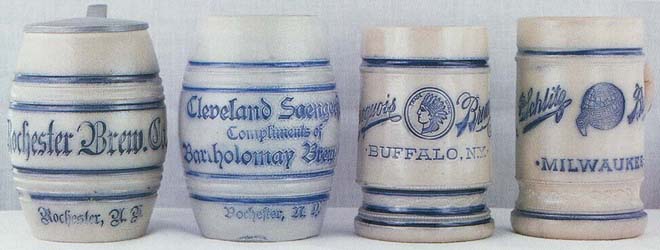

| Fig. 3 – Examples of advertising steins and mugs for breweries. |

Styles

|

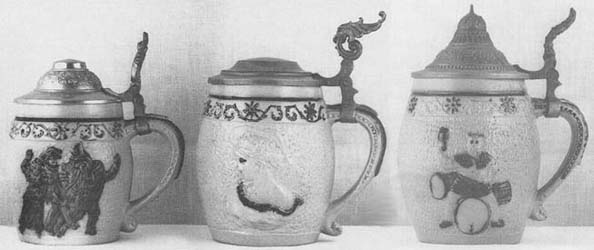

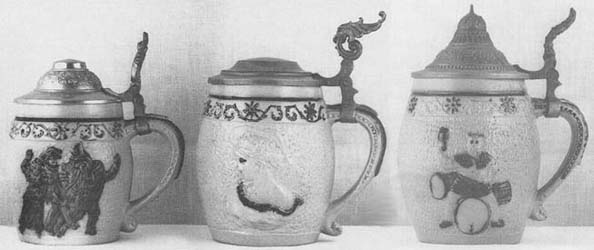

| Fig. 4 – Bismarck Head and Keg character steins. |

Because of the obvious attempt to copy German styles, many collectors own beer steins made by Whites but are not aware that they were actually manufactured in this country. It is our belief that Whites purposely sold their steins as German-made. We notice that they purposely omitted their identifying marks and often used German scenes and verses. They chose popular German themes such as tavern scenes, hunting scenes, Bavarian dress, etc. They even copied the popular Mettlach jeweled base technique on some of their steins (Figure 1). Even the few character steins that they produced were German influenced. This probably held true until the 1901 Pan American Exhibition in Buffalo, NY, where Whites displayed its wares. At that time the company tried to capture the American market and capitalize on its own name. From then on we find steins and mugs featuring American scenes such as Washington Crossing the Delaware, Buffalos, St. Augustine, and American advertising pieces for breweries, restaurants, etc. (Figure 3).

Types of Steins

All of Whites’ beer mugs and steins can be broken down into four major categories: relief; etched; reverse etched; and character. The most widely used were those with relief scenes. The etched steins just featured the scene’s outline incised onto the stein’s body. In reverse etched, the scene’s outline was raised rather than incised. Their character steins were extremely limited. We know of only the Bismarck head, the Owl, and the Keg so far (Figure 4). All of these steins were basically a monochromatic gray with possible cobalt, green or brown highlights.

|

| Fig. 5 – Relief steins 35, 36, 37, 38, 39, increasing in height from 4¾" to 8½". |

How They Were Manufactured

Most beer steins made by Whites were cast-molded rather than spun on a wheel. Liquid clay or slip was poured into a plaster mold thus creating the scene. These were done as a two-part mold or sometimes three-part mold with the mold seam right

down the center of the stein rather than on the sides. This was done because the decorations displayed were mainly in the English style, or on the side of the stein, rather than the German style which utilized the front of the stein for the center of the scene. I must point out that some of the early saltglazed pieces were hand-thrown. Because no molds were used, no mold seams would be visible. The designs were usually impressed onto the piece by using special tools.

|

| Fig. 6 – Relief stein 40, 4½" ht.; 41, 5" ht.; and 42, 5½" ht. |

During different periods Whites used different types of interior and exterior glazes. From approximately 1885-1897 a saltglaze exterior with a clear silica glaze interior was used. From approximately 1895-1899 the saltglaze exterior was still in use but often a white bristol glaze was employed on the interior. From approximately 1896-1900 a clear silica glaze was sometimes applied to the stein’s exterior while using a white interior. From approximately 1898-1907 Whites often used a bristol exterior glaze while again keeping a white interior.

Numbering System

|

| Fig. 7 — Impressed base mark “39”. |

When we examine the base of a numbered piece by Whites, we notice a 1- or 2-digit, tall and elongated impressed number (Figure 7). For many years, like its German counterparts, we believed that this number identified the mold. But this is definitely not the case. This base number identifies the size of the stein or mug body minus the lid. These mold numbers refer to a corresponding price list for Whites wares. As the number increases the stein becomes taller (Figure 5). As an example, number 35 represents a small size, number 36 slightly larger, 37, 38 and 39 and so on. Another example of a number series has number 5 as the smallest and a number 8 as the largest (Figure 1). Another numbering system starts with a low of 40 and a high of 42 (Figure 6). We also find a number series starting with 43 as the smallest and going up to 46 (Figure 8). All base numbers from 35 to 46 carry relief decorations. Also, all pieces carrying base numbers from 27 through 34 carry designs that are impressed via a special tool.

|

| Fig. 8 – Relief steins 43, 44, 45, 46, increasing in height from 5" to 7½". |

Pewter Lids and Mounts

|

| Fig. 9 — Detail of pewter lid showing criss-cross pattern in front of the tang. |

The pewter lids and attachments were probably made either at the factory or nearby. They were not as fancy or heavily gauged as the lids made in Germany. Whites lids were sometimes silver-plated but it was poorly done and wore off easily. They used half a dozen or so thumblifts but one was used most often. For some unknown reason Whites almost always used a criss-crossed pattern cut into the front part of the tang (Figure 9). This criss-crossed pattern could have been a pewterer’s guild mark.

Whites was never able to master the relief work that they copied from the German artisans. Their relief work was not as well-defined and was lacking in detail. They were also never able to master the cobalt, green or brown glazing application, often running outside of the lines.

As is customary with American-made steins, the liter marking normally found on German steins is omitted. While this is also true on some pre-war German beer steins, most carry a capacity mark. This lack of a capacity mark on American beer steins is normal and expected.

Much has been learned about these American-made German-looking steins and mugs, but there is still much to discover.

__________

*Reprinted from The Beer Stein Journal, August 1995, by permission from Gary Kirsner Auctions.